WVHS tech program receives $12K grant, supports multiple post-HS pathways

Warwick Valley Central School District emphasizes the application of the Engineering Design Process (EDP) across all grade levels and areas of study. While the EDP has a very scientific sounding name, it is actually a systematic approach that emphasizes learning by doing and can be universally applied across the entire STEAM spectrum. While it is widely understood in the context of, for example, research and development in manufacturing, the process is also used in creative disciplines, where it appears as creative brainstorming, working collaboratively to develop concepts, and peer editing.

Here is an overview of the basic steps that make up the EDP. These will give you a sense of how the process can be universally applied to different areas of study, from literacy to science, languages to math.

Here is an overview of the basic steps that make up the EDP. These will give you a sense of how the process can be universally applied to different areas of study, from literacy to science, languages to math.

- Identify a Problem

- Investigate/Brainstorm Solutions

- Choose a Solution

- Create & Test Your Solution

- Evaluate Your Outcomes

- Readjust & Try Again

- Communicate Findings

At Warwick Valley High School, as part of a robust Careers & Technology curriculum, we offer a series of courses where students apply the EDP in its most traditional ways and prepares them for post-high school life by laying the groundwork for myriad pathways that include college, trade school, or jumping right into the job force with valuable professional certifications.

This past summer, WVHS technology teacher Pat Reiser applied for and received a $12,000 grant from the Gene Haas Foundation. The foundation, established in 1999, supports manufacturing training programs through scholarship grants, partnerships with training programs, and sponsoring individual and team CNC competitions (computer numerical control). To date, the foundation has donated over $175 million in grants to support manufacturing education and the school communities that offer it.

The Gene Haas Foundation’s goal in offering this money is to introduce young people to careers in manufacturing, especially CNC technology, and not only encourage young people to pursue the many career pathways this presents, but to pave the way for them to do it!

“The advanced manufacturing industry is a big deal,” said Mr. Reiser. “There’s so much opportunity out there. And, you know, college worked for me. It was great, and works for a lot of people, but it doesn’t work for everybody. So, whatever a student decides to, whether that’s head to college, go to trade school, go to work, that’s great. At some point you’re going to need textbooks, you’re going to need tools. So, long story short, all this grant money is going directly to the students, whether it’s for scholarships, keeping our lab here at the high school up to date, even pre-professional training programs. This grant funds all of that; everybody’s going to get the same opportunity.”

Mr. Resier is part of a faculty that teaches a schedule of classes designed for students who have an interest in fields that range from engineering to machining. This year the curriculum includes a continuum of classes that begins with Intro to Engineering, which focuses on basic drawing skills with real world applications. Students use tools to explore how technology, science and math are combined to create products for everyday use. In the class Advanced AutoCAD, students learn the latest CADD software using various computer aided drawing (CAD) platforms. Students draft and design problems using CAD, and execute both 2D and 3D drawings. Engineering 101 presents the many career pathways in a career in engineering, emphasizing communication skills and the use of AutoCAD and Autodesk Fusion. Project-based problems lead to training on the high school’s in-house 3D printers, laser cutter, and CNC milling machine.

“Basically, you need machine operators who know not only how to operate the machines, but also to be to speak the same language as the programmers who program those machines. And you need people who know how to design the parts,” said Mr. Reiser. “So, students in our technology program might have their sights set on anything from studying mechanical or civil engineering in college, to attending a trade school, or even jumping right into the workforce with a lucrative manufacturing job. It’s all about making sure that everybody is talking the same language, and we’re accomplishing that goal here in Warwick.”

“Basically, you need machine operators who know not only how to operate the machines, but also to be to speak the same language as the programmers who program those machines. And you need people who know how to design the parts,” said Mr. Reiser. “So, students in our technology program might have their sights set on anything from studying mechanical or civil engineering in college, to attending a trade school, or even jumping right into the workforce with a lucrative manufacturing job. It’s all about making sure that everybody is talking the same language, and we’re accomplishing that goal here in Warwick.”

The technology space at WVHS is equipped with an impressive array of computers, software, and machines to give students invaluable opportunities for hands-on learning. There is a computer lab where students learn CAD and other forms of drafting. In two adjacent spaces there is a state-of-the-art 2D laser cutter which, as Mr. Reiser explained, serves as a steppingstone to a more complex 3D mill. To have all these resources on site is a major advantage for Warwick Valley students.

“The grant is going to go to kids in this program, who share an interest in some form of engineering or manufacturing, so it supports multiple different career pathways after school,” said Mr. Reiser. “In our program, students come into the half-year Intro to Engineering class, which is all based on hand drawing. So, learning to make a board in a title block, learning what isometric drawings are, and laying that foundation. Then, they can move on to learn things like AutoCAD; that one’s a full year class.”

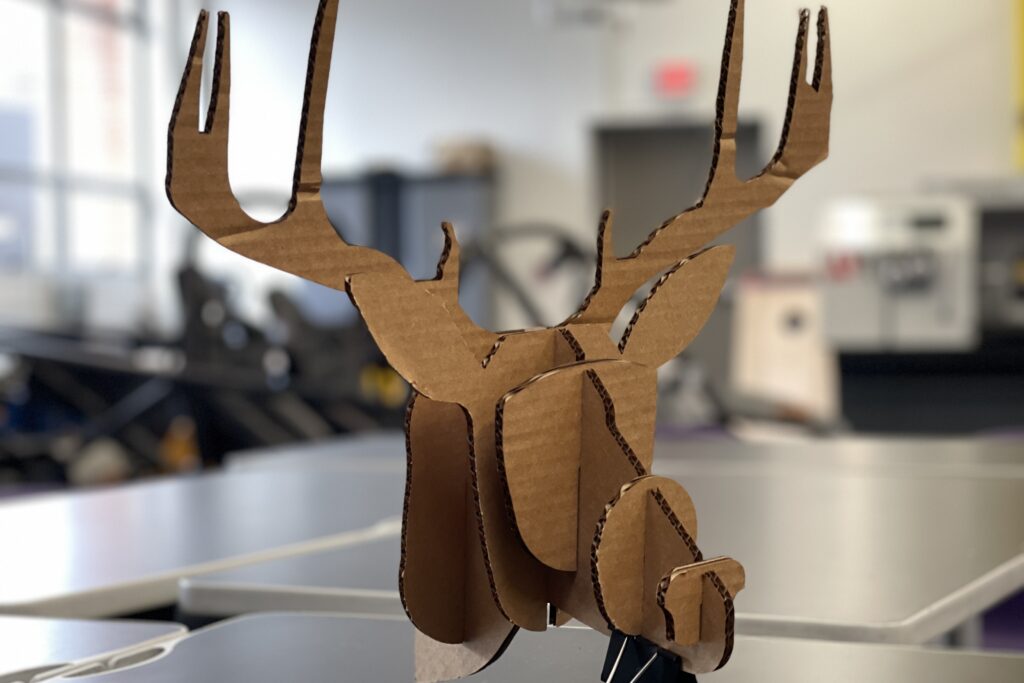

Mr. Reiser guides his students through engaging lessons with results that students can actually hold in their hands. Two student-favorite projects are his Trophy Head project and US National Park Topographic Map project, which both help students develop and then apply computer drafting and laser cutting skills.

“I’ve presented the Trophy Head project at the National Haas Technical Education Conference,” said Mr. Reiser. “You take front and side view pictures of your subject – let’s say an elk – and students have to trace everything out, then use spatial skills to figure out things like antler placement – what’s the depth, where are they on the head – where’s the nose. We program all that in, then cut 2d pieces out of cardboard on the laser machine.”

“I’ve presented the Trophy Head project at the National Haas Technical Education Conference,” said Mr. Reiser. “You take front and side view pictures of your subject – let’s say an elk – and students have to trace everything out, then use spatial skills to figure out things like antler placement – what’s the depth, where are they on the head – where’s the nose. We program all that in, then cut 2d pieces out of cardboard on the laser machine.”

The pieces are then assembled into a 3D models. Mr. Reiser said he’s had students model all kinds of things, from dragons to Homer Simpson and Mickey Mouse. He also said that the National Parks project is his personal favorite. He also said he enjoys connecting with his students on a personal level by sharing his own creative inspiration behind the project, a family road trip that he took as a kid to National Parks across the country. Mr. Reiser continues to visit national parks on vacations today. If you are wondering, like his students always do, what National Park is his personal fav, he said Acadia National Park, in Maine, is high on the list.

“Each student is given a random state, and they have to research a national park in that state. Then we use the National Department of Interiors library of topographic maps of each park to trace out different elevation layers. We cut those out on the laser and stack them on top of each other to make a real-life topo map that shows the elevation changes. Hopefully, they also learn something about the national park, which is still a big part of my life, so I like that.”

“Each student is given a random state, and they have to research a national park in that state. Then we use the National Department of Interiors library of topographic maps of each park to trace out different elevation layers. We cut those out on the laser and stack them on top of each other to make a real-life topo map that shows the elevation changes. Hopefully, they also learn something about the national park, which is still a big part of my life, so I like that.”

Students who study in the technology program at WVHS can even receive career-ready certifications as part of their high school experience!

“Oh yea, we have about 20 students who are going to be certified on the mill,” said Mr. Reiser. “They take an online course that’s put together by Haas, and at the end of that they take a hands-on course, and they’re certified. That means they can walk out of here and into a machine shop and say, ‘Okay, I’m certified by the people that made this machine, let’s go!’”

As Mr. Reiser put it, that is priceless real-life experience that, “basically puts them head and shoulders above other people walking in for those jobs. Just like anything else, actual experience is so valuable.”

Mr. Reiser looks forward to welcoming the folks from the Haas Foundation to Warwick Valley High School later this winter, who will be here to make an official presentation of the grant check. He also looks forward to having his students show off their work and show the Haas contingency around the technology space.

“I can’t say enough about the Haas Foundation and their support of technology education,” Mr. Reiser said. “Just having these funds, this money will give students all kinds of advantages – whether that’s making sure we have the latest industry tech on hand here for them to earn from or giving them that financial hand when it comes to buying textbooks or tools – it means a lot and it will go a long way. It helps us keep on doing the really exciting things here doing here in Warwick!”